The Haber Process has revolutionized farming by providing essential nutrients through synthetic fertilizers, boosting agricultural productivity globally. However, its energy-intensive nature leads to high greenhouse gas emissions and contributes to eutrophication. Despite these drawbacks, the process enables large-scale ammonia synthesis essential for fertilizer production, supporting food security. The economic significance of the Haber Process is evident through high market demand and its role in sustaining industries. Exploring sustainable alternatives like Green Electrolysis and Bioelectrochemical Synthesis highlights the importance of environmentally friendly ammonia production methods.

Takeaways

- Pros: Enhanced global farming, efficient soil nutrient replenishment, increased agricultural productivity, and meeting food demand.

- Cons: High energy consumption, significant greenhouse gas emissions, eutrophication risk, and reliance on fossil fuels.

- Impact: Contributes to carbon footprint, climate change, and eutrophication.

- Economic: Substantial investment, market demand for ammonia, and support for industries.

- Demand: Crucial in fertilizers, industrial use, linked to agriculture, and must adapt to market changes.

Increased Agricultural Productivity

The Haber Process has greatly enhanced agricultural productivity through the production of synthetic fertilizers. By converting atmospheric nitrogen into ammonia, Fritz Haber's invention revolutionized farming practices worldwide.

Synthetic fertilizers made from ammonia contain essential nutrients like nitrogen, phosphorus, and potassium, vital for plant growth. This process has enabled farmers to replenish soil nutrients quickly and efficiently, leading to increased crop yields and improved food security.

The availability of synthetic fertilizers has allowed farmers to cultivate crops more intensively and on a larger scale. With the Haber Process, agricultural productivity has soared, meeting the demands of a growing global population.

The ability to produce fertilizers in large quantities has transformed the agricultural industry, making it possible to sustainably feed billions of people.

However, the increased use of synthetic fertilizers has raised concerns about environmental degradation. Runoff from fields can pollute water sources, and the over-application of fertilizers can lead to soil acidification and nutrient imbalances.

Despite these challenges, the Haber Process remains a cornerstone of modern agriculture, driving increased productivity and economic growth in the sector.

Energy Intensive Process

The Haber Process is recognized for being an energy-intensive method due to the high temperatures and pressures required for ammonia synthesis.

Analyzing the energy consumption of this process is essential to understanding its environmental impact and sustainability.

Exploring efficiency improvements and alternative energy sources could help mitigate the energy intensity associated with the Haber Process.

Energy Consumption Analysis

Energy consumption in the Haber Process plays a critical role in determining its overall efficiency and cost-effectiveness. The Haber Process is known for being energy-intensive due to the high temperatures and pressures required for the synthesis of ammonia from nitrogen and hydrogen. The primary energy input in this process is for the compression of nitrogen and hydrogen gases, as well as for maintaining the reactor at ideal conditions.

The energy consumption analysis of the Haber Process reveals that a significant amount of energy is needed to drive the reaction forward. This high energy demand contributes to the operational costs associated with the process. Additionally, the energy-intensive nature of the Haber Process leads to environmental concerns due to the reliance on fossil fuels for energy generation.

Efforts are being made to optimize the energy consumption in the Haber Process through technological advancements such as improved catalysts and reactor designs. By reducing energy consumption, the overall efficiency and sustainability of the process can be enhanced.

Efficiency and Alternatives

Efforts are continually being made to enhance the efficiency of the Haber Process and explore alternative methods for ammonia synthesis. The Haber Process is known for its high energy consumption, with the production of one ton of ammonia requiring around 33 GJ of energy. Improving the efficiency of this process is vital to reduce energy consumption and lower production costs.

One way to enhance efficiency is through catalyst development, aiming to increase the rate of ammonia synthesis while lowering the operating temperature and pressure. Another approach is the integration of renewable energy sources, such as wind or solar power, to provide the necessary energy for ammonia production.

Alternative methods to the traditional energy-intensive process are also being researched. One promising avenue is electrochemical synthesis, which uses electricity to drive the ammonia synthesis reaction. This method has the potential to be more energy-efficient and environmentally friendly compared to the Haber Process. However, challenges such as improving selectivity and reducing production costs need to be addressed before widespread adoption.

Environmental Impacts

Environmental considerations play a significant role in evaluating the sustainability of the Haber Process. The process has several environmental impacts that need to be carefully assessed:

- Greenhouse Gas Emissions:

One of the major drawbacks of the Haber Process is its significant contribution to greenhouse gas emissions, particularly carbon dioxide. The production of ammonia involves the consumption of a large amount of natural gas, which releases CO2 into the atmosphere.

- Eutrophication:

The excessive use of ammonia-based fertilizers produced through the Haber Process can lead to eutrophication. When these fertilizers runoff into water bodies, they can cause excessive algae growth, leading to oxygen depletion and harm to aquatic life.

- Energy Consumption:

The Haber Process is energy-intensive, requiring high temperatures and pressures for ammonia synthesis. This high energy demand often leads to increased reliance on fossil fuels, exacerbating the carbon footprint of the process and contributing to climate change.

Global Fertilizer Production

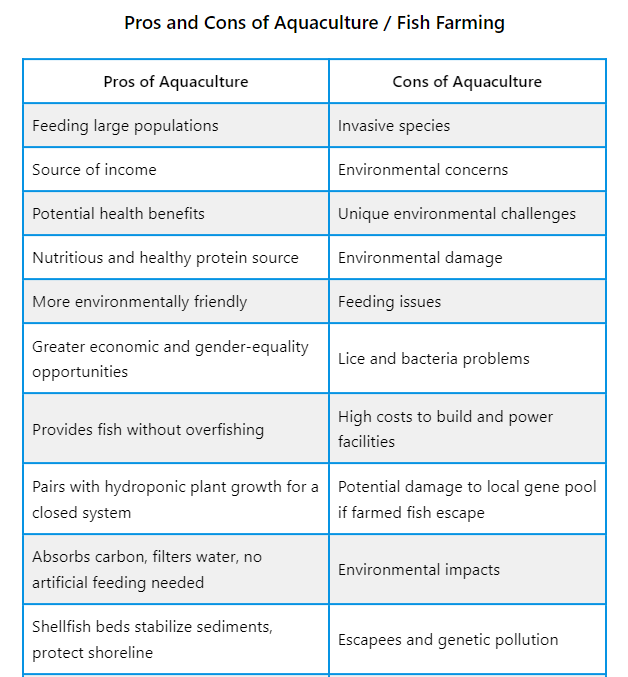

How does the Haber Process contribute to the global production of fertilizers? The Haber Process plays a crucial role in global fertilizer production by enabling the large-scale synthesis of ammonia. This ammonia serves as a key component in the production of nitrogen-based fertilizers, such as ammonium nitrate, urea, and ammonium phosphate. These fertilizers are essential for replenishing soil nutrients, enhancing crop yields, and ensuring food security worldwide. The Haber Process allows for the efficient conversion of atmospheric nitrogen into ammonia, providing a sustainable solution to meet the growing demand for fertilizers in agriculture.

| Pros of Haber Process | Cons of Haber Process |

|---|---|

| High ammonia production rates | Reliance on fossil fuels |

| Essential for global food production | Energy-intensive process |

| Enables agricultural sustainability | Environmental impacts |

| Supports food security | Costly infrastructure requirements |

Economic Significance

The economic significance of the Haber Process is profound, with key points revolving around cost implications and market demand.

Understanding the cost implications of producing ammonia through this process provides insights into its feasibility and sustainability for industries.

Additionally, the market demand for ammonia as an essential component in fertilizer production further underscores the economic importance of the Haber Process.

Cost Implications

One of the key considerations when evaluating the Haber Process is its economic significance, especially with regards to cost implications. Here are three critical points to ponder:

- Initial Investment: The implementation of the Haber Process requires substantial capital investment in equipment and infrastructure. The cost of setting up the necessary plants for ammonia production can be substantial, impacting the overall feasibility of the process.

- Operational Costs: Beyond the initial investment, ongoing operational costs are a vital factor in evaluating the economic viability of the Haber Process. Expenses related to energy consumption, raw materials, maintenance, and labor all contribute to the total cost of ammonia production.

- Market Price Volatility: The cost implications of the Haber Process are also influenced by market dynamics. Fluctuations in the prices of key inputs like natural gas and nitrogen can have a significant impact on the overall cost of ammonia production, affecting the profitability of the process.

Considering these cost implications is essential for stakeholders in the Haber Process to make informed decisions regarding its economic feasibility.

Market Demand

In evaluating the economic significance of the Haber Process, the market demand for ammonia plays a pivotal role in shaping its viability and sustainability. As ammonia is a key component in fertilizers, demand is closely tied to agricultural activities. The global population growth and increasing food requirements have led to a consistent demand for ammonia-based fertilizers. This steady market demand not only guarantees a stable market for ammonia production but also drives innovation and efficiency in the Haber Process.

Moreover, the versatility of ammonia extends beyond fertilizers, with applications in various industries such as pharmaceuticals, cleaning products, and chemical manufacturing. This diverse range of uses further contributes to the market demand for ammonia, making the Haber Process a valuable industrial method.

However, fluctuations in agricultural practices, environmental concerns regarding fertilizer usage, and the development of alternative technologies could influence the market demand for ammonia in the future. To maintain its economic significance, the Haber Process must adapt to changing market demands and continue to meet the needs of various industries.

Sustainable Alternatives

Exploring sustainable alternatives to the Haber Process is essential in advancing environmentally friendly methods of ammonia production. As the demand for ammonia continues to grow, finding more sustainable ways to produce it becomes increasingly important.

Here are three sustainable alternatives that show promise in reducing the environmental impact of ammonia production:

- Green Electrolysis: Utilizing renewable energy sources like wind or solar power to power electrolysis processes can produce hydrogen sustainably. This green hydrogen can then be used in Haber-Bosch-like reactions to synthesize ammonia without the need for fossil fuels.

- Haber-Bosch with Renewable Hydrogen: Instead of relying on natural gas to produce hydrogen for the Haber Process, renewable hydrogen produced through electrolysis using renewable energy sources can be employed. This method eliminates the carbon footprint associated with traditional Haber-Bosch reactions.

- Bioelectrochemical Synthesis: Bioelectrochemical systems can use bacteria to convert nitrogen into ammonia under mild conditions, offering a potential eco-friendly alternative to the energy-intensive Haber Process.

Frequently Asked Questions

Is the Haber Process Suitable for Small-Scale Farming?

The Haber Process, known for its ability to synthesize ammonia from nitrogen and hydrogen, may not be ideal for small-scale farming due to its large-scale infrastructure requirements. Alternative nitrogen sources might be more practical.

How Does the Haber Process Impact Water Resources?

The Haber process, essential for ammonia production in fertilizers, has a substantial impact on water resources due to its high water consumption. The process requires large volumes of water for cooling and as a reactant, potentially straining local water supplies.

What Are the Social Implications of Global Fertilizer Production?

The social implications of global fertilizer production encompass environmental concerns, economic disparities, and food security issues. Balancing the need for agricultural productivity with sustainable practices is crucial to address these challenges and guarantee a stable future for all stakeholders.

Can the Haber Process Be Used for Other Industrial Purposes?

The Haber process, known for producing ammonia, can be adapted for various industrial purposes beyond fertilizer production. Its nitrogen fixation capabilities hold potential for applications in pharmaceuticals, chemicals, and fuel production, offering versatility and economic benefits.

Are There Any Health Risks Associated With Haber Process Products?

The Haber Process involves the production of ammonia, a useful chemical compound. Health risks associated with Haber Process products are mainly due to the toxicity of ammonia itself, such as irritation of the respiratory system and skin.

Conclusion

To sum up, the haber process has both advantages and disadvantages. It plays an essential role in increasing agricultural productivity but is an energy-intensive process that has negative environmental impacts.

Despite its economic significance and global fertilizer production, the haber process also raises concerns about sustainability. Alternative methods are being explored to address these issues and create a more environmentally friendly and sustainable approach to nitrogen fixation.